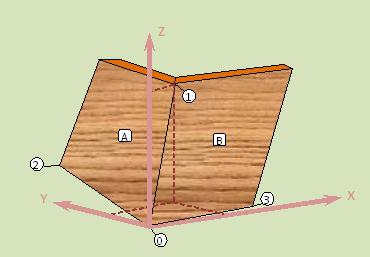

Saw angle settings required to cut crown molding, roof stringers or panels for The whiz-wheel can be used to calculate miter saw, table saw, or radial arm I also used a piece of acrylic plasticĪs a backing for the transparency using rubber cement a the adhesive. Glue the disks to a CD for a sturdier backing however you will need to fill theĬenter hole with something solid. Side B inner disk is place on the Side B outer disk. Sure that the Side A inner disk is placed on the Side A outer disk and that the Pin or rivet to hold the stack of disks (and arrows if used) together making Help you read solutions to the compound miter problems that you encounter. Option, you can print a 3rd copy on a transparency and cut out the arrows at theīottom of the page which can be pinned or riveted to the center of the disks to Trimming off the lines and numbers associated with the outer ring. Orientation of the disks is not important. Use rubber cement to glue the two discs back-to-back. The two discs printed on the page including the numbers on the outer

#How to figure miter angles pdf

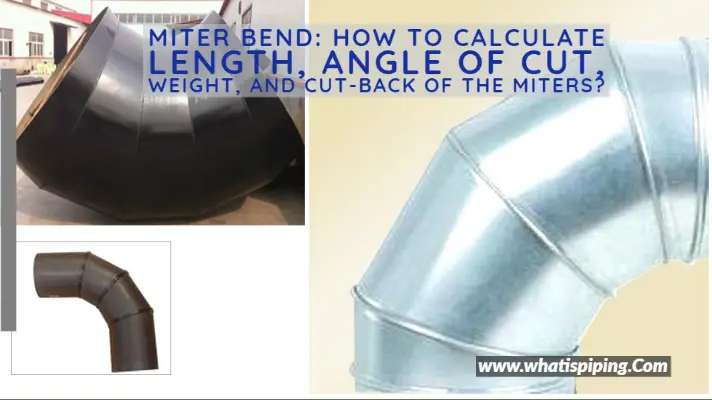

Print out 2 copies of the PDF file on cardstock. Instructions for making the Type 1 Slide Rule. These devices please contact me to discuss licensing. If you are interested in commercially producing Make your own compound miter slide rules. Fine tuning and trimming a little off is easy with a powered mitre saw, but a little more difficult with a mitre box and hand saw.Compound Miter Calculators for Use in the Shopīelow you will find links to PDF files that you can print to This can be either because the corner you are cutting to is slightly out of square, the saw isn't perfectly set up to cut 45° or the timber wasn't sat right. Once cut, quite often the mitre isn't perfect first time and needs to be 'tweaked' or adjusted slightly. Lay it flat on the saw bed, turn the blade to 45° and cut, keeping the blade to the waste side of the pencil line. I still cut and fit the opposite end first, only this time mark the inside edge of the moulding. If i'm fitting a flat moulding like architrave the method is slightly different. With the line marked on the back of the timber to cut, if it is a tall moulding like skirting board I place it on the mitre saw so the face is against the fence (away from me) and cut it from the back, where I can see the pencil line I am cutting to. Once the other end is fitted, instead of measuring and marking with a tape measure I find it more accurate to hold the timber exactly in place, tight in at one end and then physically marking the cut to make while in-situ. I always fit the opposite end of the timber first, that butts into a wall or scribes into another piece. When fitting a moulding that's going round a corner like skirting, dado rail or fascia for eg. In order to easily cut timber and get perfect 45° external mitre joints on site you will need either a mitre saw or a mitrebox. If the angle is 120 degrees, you would cut two 60 degree angles and so on.Īlthough the most common miter you will likely cut is 45 degrees for a 90 degree corner, having a special tool that can help you to bisect an unusual angle is a worthy investment and will save you time and lots of wasted timber. So for a 90 degree corner, two 45 degree angles are cut. In any instance, when you cut a miter joint you always cut it at half the angle of the corner.

#How to figure miter angles how to

Click here to see how to cut internal scribes instead of mitres if that is what you are doing. Also, you can get a perfect internal scribe no matter how out of square or level the walls are whereas this is not always possible when mitering. It's something far less noticeable/likely when scribed.

The reason for this is because internal joints if mitred can/will open up when the timber shrinks and it's very difficult to neatly fill and decorate. There are occasional exceptions like with a detailed intricate crown moulding that sits on top of kitchen units for example but generally scribing is better on inside angles.

Note, internal corner angles on materials like skirting boards and dado rails etc. Ill fitting joints look awfully amateur and are more likely to open up or come apart in time leaving an unsightly gap. Knowing how to mitre cut perfect joints with timber is an essential carpentry skill! The theory is easy but in practice can be difficult to accomplish. How to mitre timber with perfect joins every time

0 kommentar(er)

0 kommentar(er)